If you are in the food and beverage industry, mixing and blending are critical components for processes that directly affect quality, safety, and costs throughout the supply chain. Whether ensuring homogenous blends of finished product or maintaining ingredient stability, Brawn mixers bring precise, hygienic operation to each stage of a food or beverage processing operation.

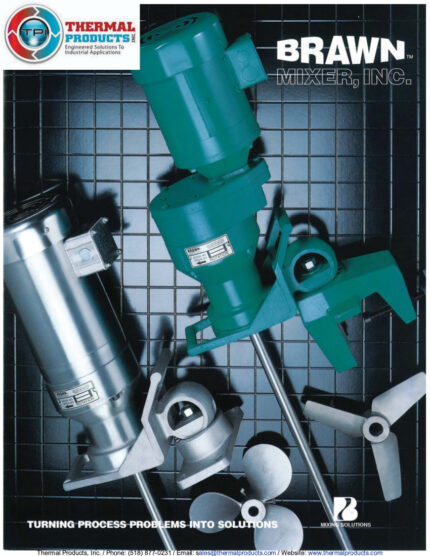

PROCESSES

Liquid-liquid blending

Solid suspension

Dissolution

Gas dispersion

Emulsions

Multi-phase

Heat transfer

High viscosity

Fermentation

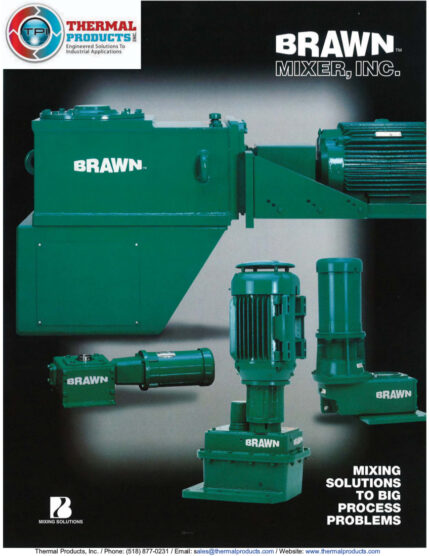

DESIGN CAPABILITIES

Open/closed tank

High temperature

High pressure

Special alloy wetted parts

Hazardous environment

FDA/USDA documentation

Sanitary/CIP construction

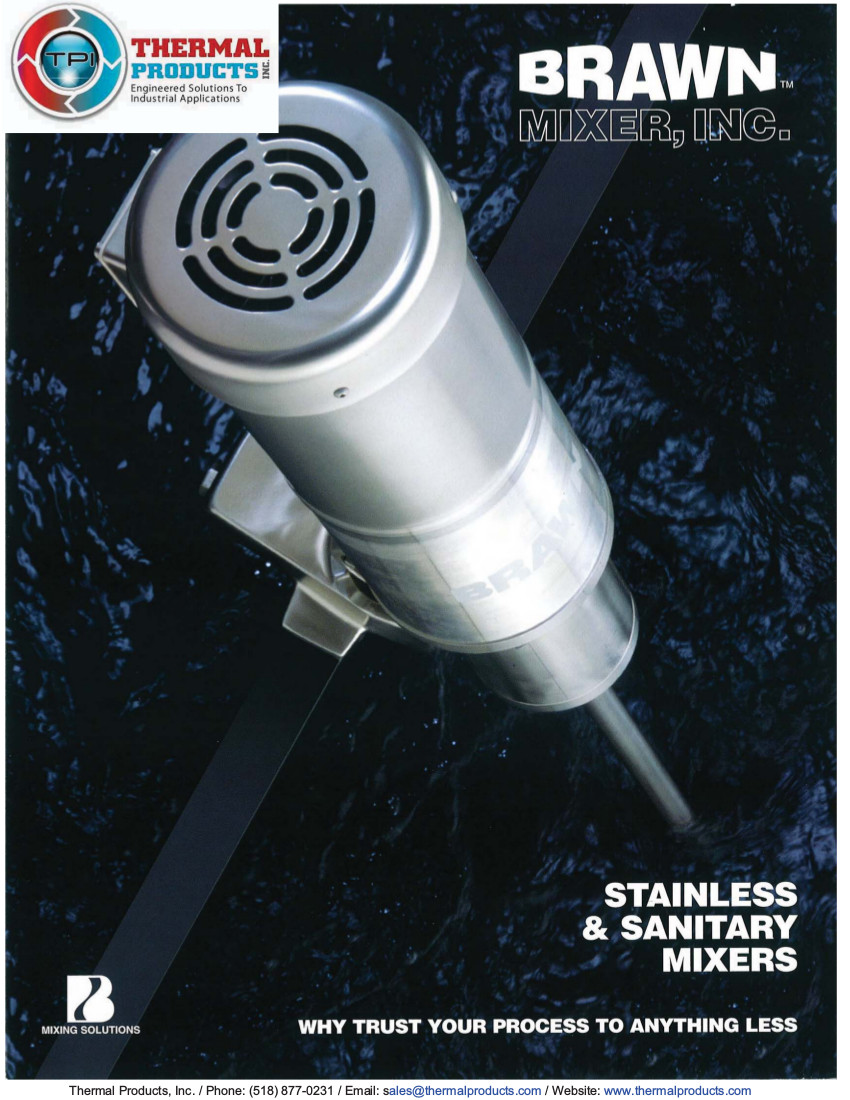

Hygienic Mixer Design

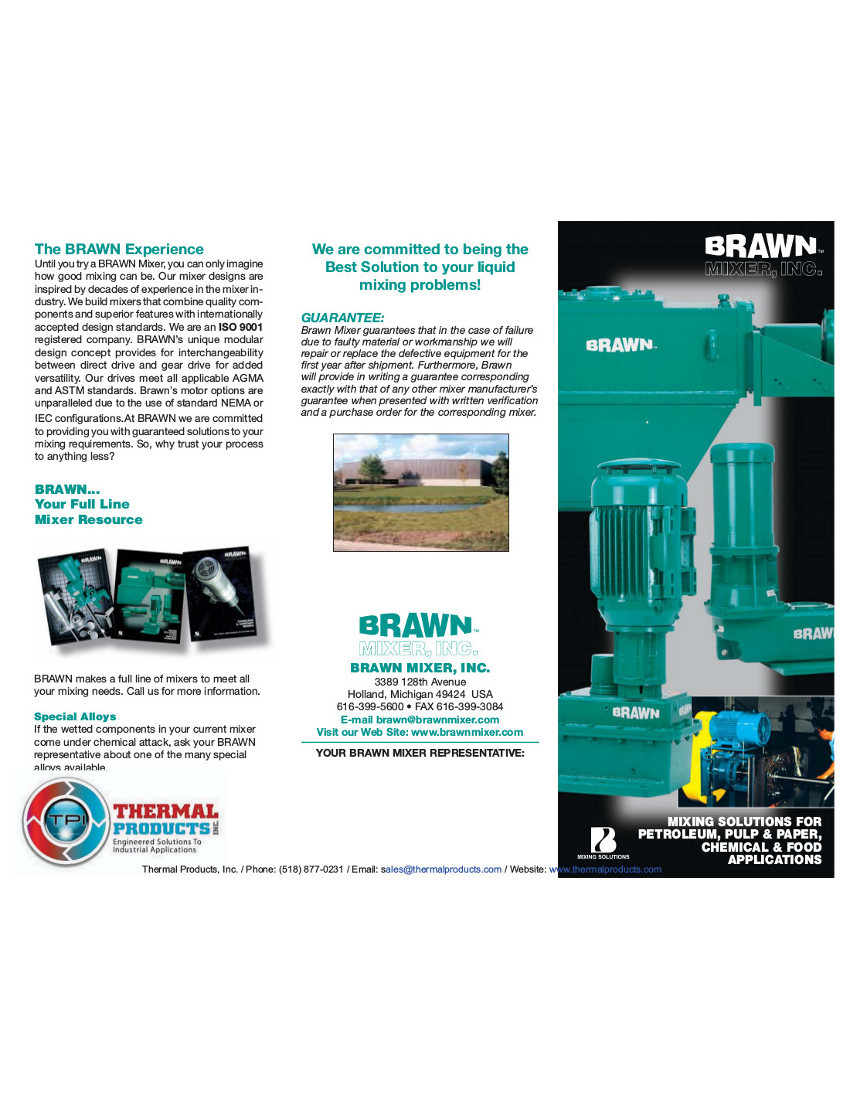

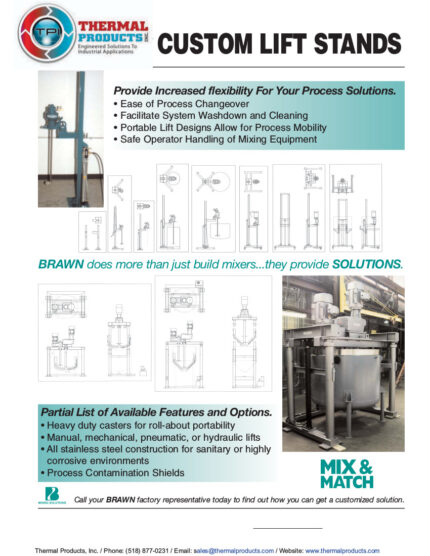

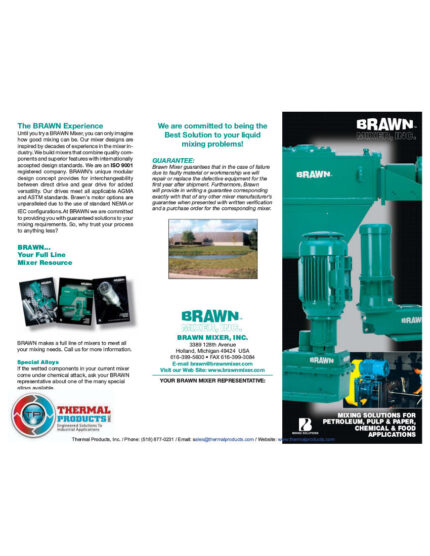

Applications with hygienic or sanitary specifications are common in the food, beverage, and nutraceutical industries. The Brawn Mixer application engineering team evaluates the entire process chain, and takes into account risk factors that extend beyond the mixing operation alone to ensure each mixer contributes positively to overall quality, safety, and optimization goals. Mixers can be designed to conform to applicable standards from all major regulatory bodies, including the FDA, cGMP, USDA, and USP. Comprehensive documentation to fulfill validation requirements is also available.

Brawn mixers are designed to meet hygienic standards are cleanable via either customer or OEM-supplied SIP or CIP systems. All-stainless-steel construction is available for many mixer configurations; drive assemblies can also be coated with Steel-It paint.

If you have questions, please contact Thermal Products to dsicuss your project.