Improving Your Plant Compressed Air Efficiency

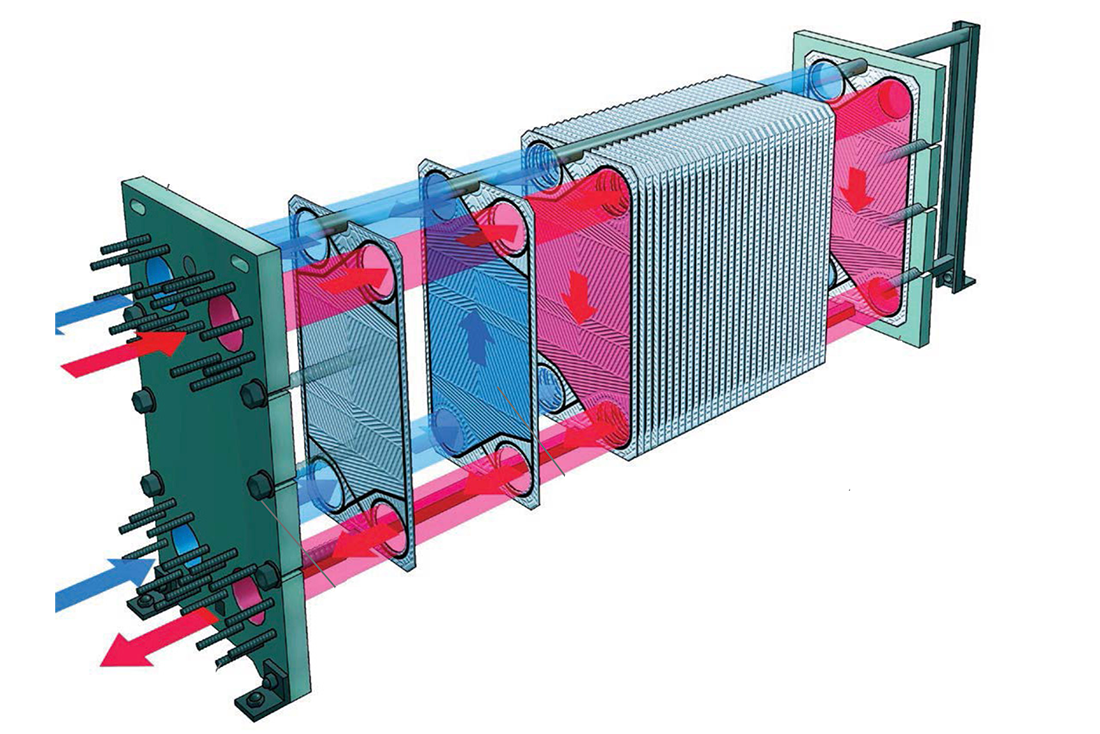

One of Thermal Products customers, in the nonwoven’s industry, desired to increase their plant compressed air throughput while maintaining the current temperature delta to their process. This created more efficiencies downstream that they wished to recognize. The existing After-cooler was the limiting factor in achieving that. The overall size did not allow for increasing the air flow rate without increasing the pressure drop beyond acceptable levels. Secondary to that, the tube bundle and heat transfer surface area design was not suitable for this increase. Thermal Products along with our manufacturing partner, API Heat Transfer, Basco division, was asked to design a new after-cooler to specific design specifications. The design required very minimal air side pressure drop while needing a 20% design increase in air flow, all while maintaining similar installation footprint. Thermal Products designed an API Basco type ES, or extended surface heat exchanger. The design included a tri-pitch tube bundle with admiralty tubes and an aggressive FPI (Fins Per Inch) on the aluminum fin surface of the tube bundle. The Basco Type ES heat exchanger allows very high heat transfer surface area in a small foot print. This design allowed a similar foot print, while increasing the customer heat load and air flow requirements.

Thermal Products and can offer standardized or fully customized heat exchangers, as in our Type ES Heat Exchanger. We can offer TEMA designed heat exchangers with ASME Code, European PED, Koren Code and many other certifications. Please contact us to discuss your application.