What is needed to design and quote a shell and tube heat exchanger?

When the design engineers at Thermal Products have a request from a customer to design a shell and tube exchanger, we will consider many factors, including:

- What codes and/or standards will guide the design: ASME Boiler and Pressure Vessel Code, TEMA standards, and API (American Petroleum Institute), PED (Pressure Equipment Directive – Europe), CRN (Canadian Registration Number). All guide our engineers to offer the most optimally designed shell and tube heat exchanger while ensuring safety, reliability, and efficiency.

- Process requirements: These include process and utility fluid or gas types, flow rates, process side inlet temperature, process side outlet temperature, utility side inlet temperature, and operating pressure.

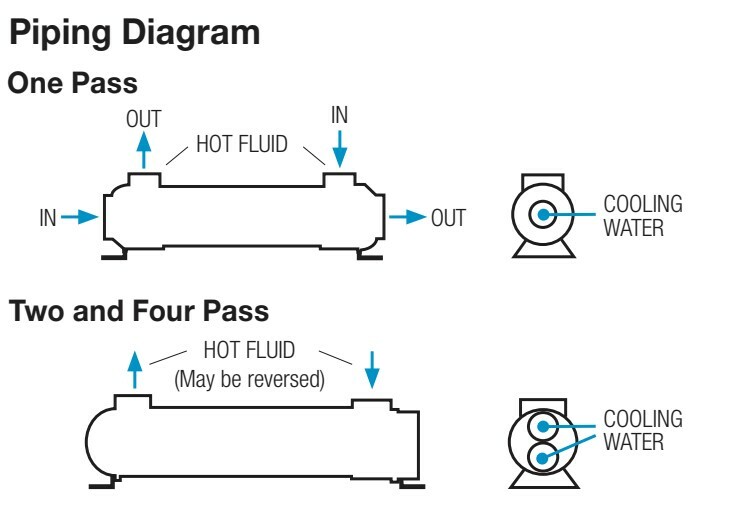

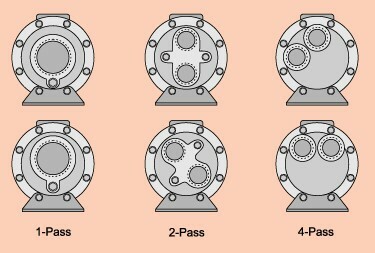

- Configurations: Here our design engineers will take into account our customer needs and requests for how their shell and tube heat exchanger will look.

- What orientation do you need your shell and tube heat exchanger? Horizontal, vertical or sloped for drainability?

- Do you need all tube side connections on one side?

- Where do you want your shell side connections oriented on the shell? We can orient them 360 degrees around the shell in most cases to better suit your process needs.

- Are NPT or Flanged connection needed?

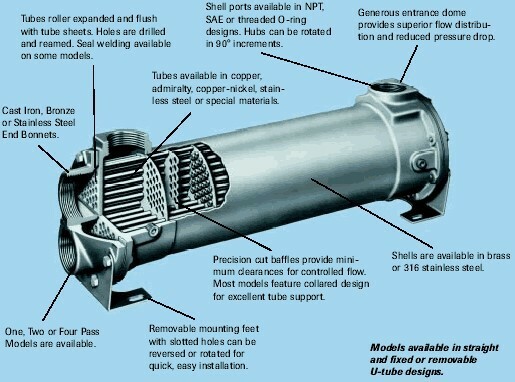

- Design elements: Baffle cut, spacing, and orientation, as well as tube-side channel and nozzle design, can all affect performance with regards to pressure drop, velocity, heat transfer rate and final footprint size.

- Construction materials: Shell materials can include carbon steel, stainless steel, or alloys, while tubes can be copper, aluminum, stainless steel, or other alloys.

- Physical space: The available floor space for installation is also a consideration.

Please look for Thermal Products Shell and Tube Heat Exchanger RFQ form or click here.