News & Updates

What are the Benefits of Using a TEMA Type BEP vs Type BEU in Gas Heating Applications?

North America has a vast network of natural gas pipelines to carry the needed natural gas to our homes, business and manufacturing plants. To move natural gas, a series of compression stations or utility gas let down stations or regulation stations are required to manage the transmission pressure of natural gas being transported through the gas pipelines. The natural gas transmitted through the pipelines is reduced in pressure from the transmission pressure (up to 700 psi) down to a pressure range of 30-50 psi for local use. As the pressure is let down, the gas expands. During the expansion of the gas it will cool, generally in the range of 10F for each atmosphere of expansion. As the gas cools, the water vapor in the gas stream will freeze if the temperature of the gas drops low enough. Ice formation in the gas stream can cause significant damage in valves, piping, heat exchangers and compressors in the pipeline. To avoid the potential problem of ice formation, the gas is heated prior to the pressure let down. Typically, the natural gas is heated from approximately 320F to 850F using a hot glycol solution or thermal oil at 1500F.

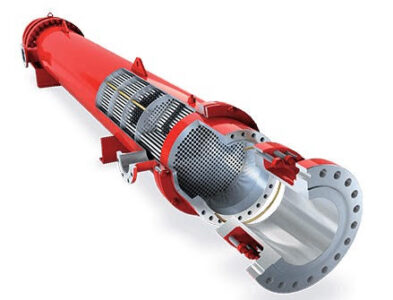

Thermal Products recommends a high-pressure API Heat Transfer Basco TEMA Type BEP or BEU shell & tube heat exchanger for natural gas heaters. A type BEP is a straight through design allowing the heat exchanger to easily be installed in the pipeline. With the high-pressure gas flowing through the tubes, the BEP’s floating tube sheet design protects the unit from the stresses of differential thermal expansion.

The U-Tube configuration of the type BEU allows it to handle differential thermal expansion since the bent tubing is inherently free to expand. Both the BEP and BEU designs avoid the use of packing on the tube side thus minimizing the chance for a dangerous natural gas leak to the atmosphere. A glycol solution or thermal oil from a Thermal Fluid Heater is circulated through the shell side of the heat exchanger and returned to the boiler. Natural gas heaters are sized using the lowest gas pressure case, since the maximum tube velocity is obtained from the lowest operating pressure.

A variety of materials can be used but generally the heat exchanger is constructed entirely of carbon steel. This provides the required strength for the critical operating conditions while minimizing the cost of the heat exchanger. A rupture disc is normally provided on the shell side to protect the heat exchanger in the unlikely event of a tube failure. The rupture disc allows a safe escape of the high-pressure gas should a tube rupture allowing the gas to enter the shell side of the heat exchanger.

Contact Thermal Products for help with your application!