News & Updates

Understanding Gas Heaters

Gas heaters are employed in gas regulation stations as the gas in the pipeline is reduced to around 30-50 psi from 700 psi in most cases. As the gas pressure is reduced, the gas expands and cools. As it cools, the water particles in the gas can freeze if the gas drops low enough, causing problems in the valves and piping. To avoid the issue of ice formation, the gas is heated to 85F prior to the pressure reduction using Hot Glycol, Thermal Oil or Electricity.

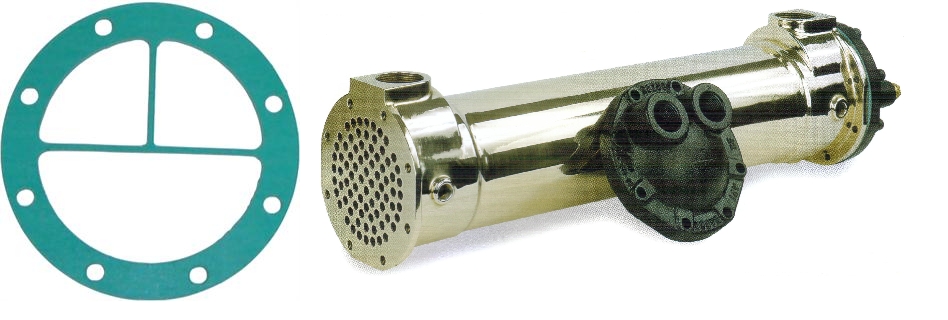

When using thermal oil or glycol we would design a TEMA class shell & tube exchanger in a type BEP or BEU. Both designs are excellent for pipeline applications for ease of install, cleanability and thermal expansion.

If you choose to use electricity, then we would design a circulation heater, whereby gas would be passed through the shell using the electric elements to heat your gas.

These are some of the certifications we currently have for these designs.

ASME PED CSA UL NEMA

In any of these cases, we would recommend a rupture disk to not put at risk the heat exchanger being damaged due to over pressurization.

Thermal Products can assist you with all your gas pipeline heating needs. Employing a shell & tube exchanger or electric circulation heater, we can handle all your design needs quickly and accurately.

Please see accompanying application literature.

Why the Circulation Heater Design You Specify Matters

Natural Gas Heaters