Selecting the proper TEMA Type Heat Exchanger

TEMA stands for “Tubular Exchangers Manufacturers Association” and is a set of standards that were developed by leading shell and tube manufacturers. These standards define the style of heat exchanger and the machining and assembly tolerances. One of the advantages of selecting a shell & tube manufacturer that builds to TEMA specifications is that the end-user is assured that they will receive and install a piece of equipment that is built to certain specification’s and criteria.

There are 3 major TEMA classifications, which are as follows;

TEMA C – General Service

TEMA B – Chemical Service

TEMA R – Refinery Service

TEMA C is the least restrictive and most widely used. TEMA B and TEMA R are similar in requirements and typically require features like, confined gaskets joints, spiral wound gaskets along with some greater minimum thicknesses on some parts.

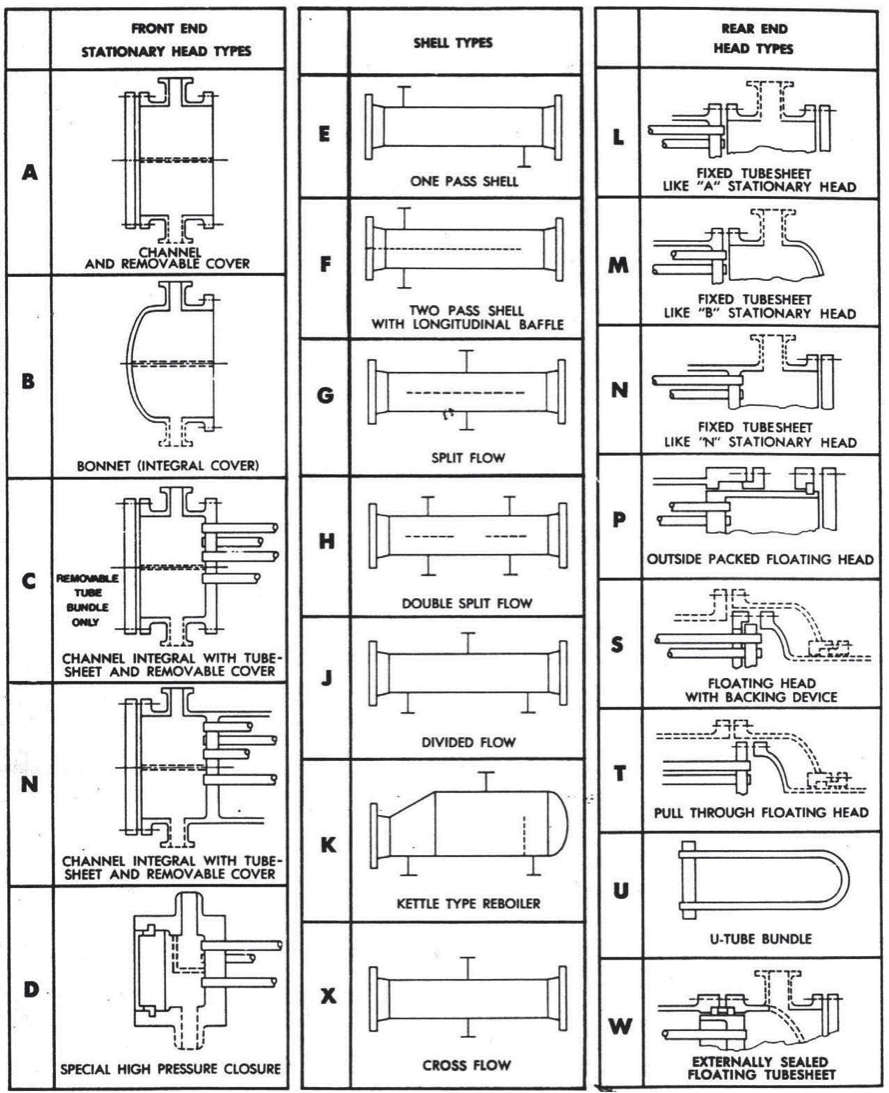

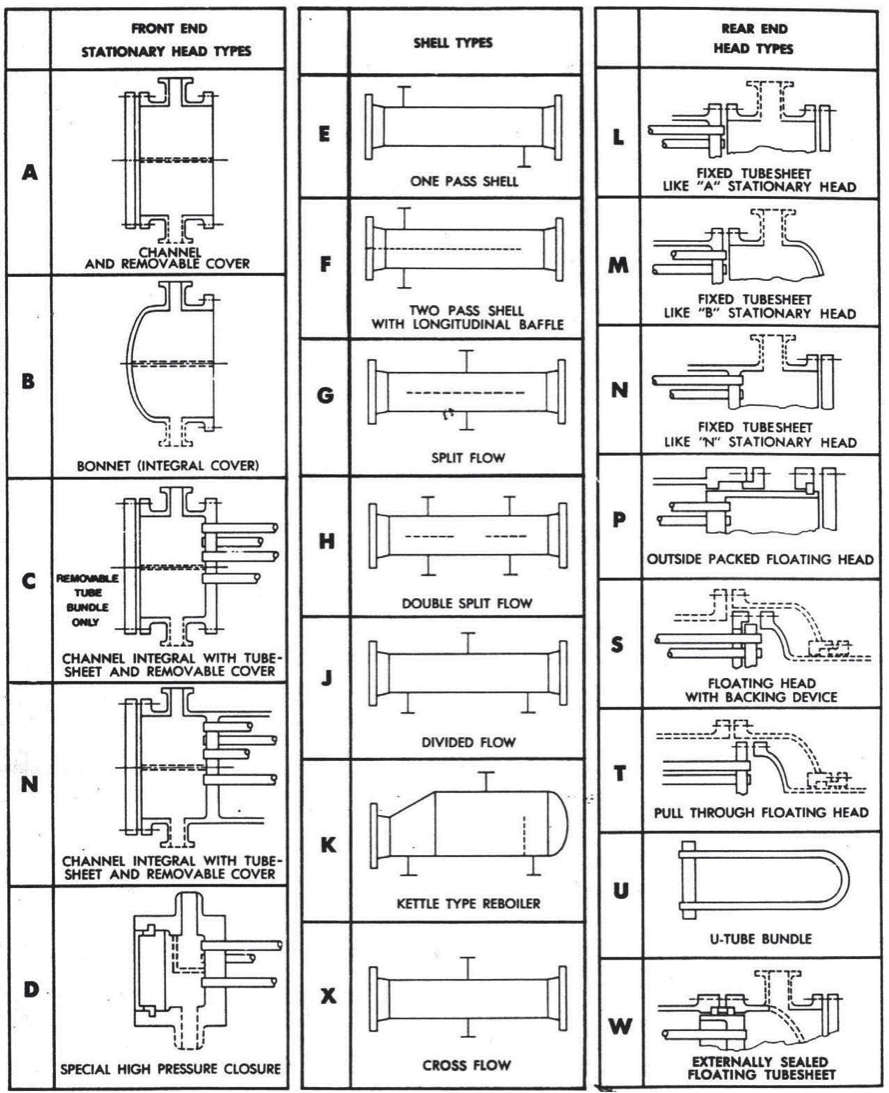

TEMA designations refer to portions of the unit that make up the complete heat exchanger. IE: TEMA Type BEM would have the “B” representing the front head, the “E” the core or middle section and M representing the rear head designs.

The figure below is helpful in visualizing each segment.

Figure: 1

TEMA Designs Available:

Straight Tube and Fixed Tube Sheet: Types BEM, AEM, NEN, etc

This design is the simplest design and most economical in most cases. The tube sheet is welded to the shell and heads are bolts to the tube sheet.

Advantages:

• Less costly than removable bundle designs

• Capable of multiple pass designs

Limitations:

• Shell side can only be cleaned by a chemical solution

• No ability to absorb thermal expansion between the outer shell and tube bundle

Removable Bundle and Externally Sealed Floating Tube sheet: Type AEW, BEW

This design allows for the tube bundle to be removed for inspection and cleaning. With Basco’s OP design, the head can be removed for inspection of the interior of the tubes, without releasing the pressure on the shell side process.

Advantages:

• Floating tube sheet allows for Thermal Expansion

• Shell side can be inspected and mechanical cleaned

• Tube bundle can be replaced or repaired without breaking the piping on the shell side.

• Maximum surface area for specified shell diameter for a removable bundle

Limitations:

• Tube side passes are limited to one or two passes

• Packing material limits operational pressure and temperature

Applications:

• Intercoolers and After coolers

• Coolers with water in tubes

• Jacket water coolers and Oil coolers

Removable Bundle, Outside Packed Head: Type BEP, AEP, etc.

This design allows for the easy removal, inspection and cleaning of the shell side circuit and shell interior without removing the floating head cover. Special floating tube sheet prevents intermixing of fluids. In most cases, straight tube removable bundles are a more costly design that U-tube designs.

Advantages:

• Floating tube sheet allows for differential thermal expansion between the shell and tube bundle

• The tube bundle can be repaired or replaced without disturbing shell piping

• Tubes can be serviced without disturbing the tube side piping on AEP designs

• Less costly than TEMA BES and BET designs

• Provides a large bundle area entrance reducing the need for entrance domes for proper fluid distribution

Applications:

• Flammable or toxic liquids in the tube side circuit

• Good for high fouling fluids in the tube side circuit

Removable Bundle, Internal Split Ring Floating Head: Type AES, BES, Etc.

These designs are best for applications when frequent tube bundle removal is necessary. More favorable to thermal shock than AEW or BEW designs. This design is suitable for volatile or toxic fluids.

Advantages:

• Floating head design allows for thermal expansion

• Maximum surface area for specified shell diameter than a “pull through” designs like AET or BET

• Available to multiple passes on tube side

Limitations:

• Shell cover, split ring and floating head cover must be removed to remove the tube bundle, results in higher maintenance costs

Applications:

• Chemical processing applications for toxic fluids

• Special gas intercoolers and after coolers

Removable Bundle, Pull Through Floating Head: Type AET, BET etc.

These designs are best for applications when frequent tube bundle removal is necessary as the floating head is bolted directly to the floating tube sheet. This allows the bundle to be pulled complete, with the head.

Advantages:

• Floating head allows for thermal expansion

• Shell side can be inspected or mechanically cleaned

• Provide a large shell side nozzle entrance area for proper distribution over the bundle

• Multiple tube side passes available

• Suitable for volatile or toxic fluids

Applications:

• Chemical processing applications for toxic fluids

• General industrial applications requiring frequent cleaning

• Hydrocarbon fluid condensers

Removable Bundle, U-tube: Type BEU, AEU etc.

This design is best suited for maximum thermal expansion applications. Each tube has the ability to expand and contract independently. This design is suitable for high thermal shock applications. U-tube bundles are very economical.

Advantages:

• The U-tube design not only allows for differential thermal expansion between the shell and tube bundle, but also each tube individually.

• Shell side can be inspected and cleaned

• Least costly design for removable bundles

• Multiple tube side passes are available

• Capable of handling high thermal shock applications

• Bundle can be removed from one end for cleaning or replacement

Applications:

• Oil, chemical and water heating applications

• Optimal for steam to liquid applications.