Enerquip

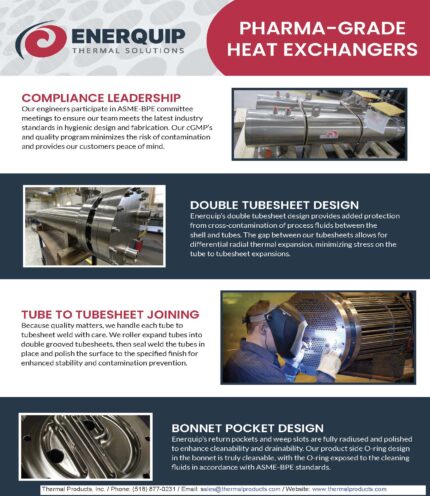

Since 1985, Enerquip Thermal Solutions has been producing high-quality shell and tube heat exchangers, vapor condensers, and other process equipment for sanitary and industrial applications.

Their reputation for custom, innovative designs, and high-quality fabrication, have earned them preferred supplier status with leading companies in a variety of markets, including Pharmaceutical, Food & Beverage, Dairy, Cannabis, Personal & Pet Care, Chemical, Asphalt, Biodiesel & Renewable Energy, Refining, Tank Terminal, Commercial, and more.

Using the experience gained from building literally thousands of different exchangers, Enerquip applies leading design software and modern manufacturing methods each day on every new design. Enerquip’s customers benefit from receiving the right heat exchanger solution for their unique processing need. As an ASME shop, an on-site third-party inspector ensures that each design meets required codes such as ASME VIII Div 1, TEMA B, C or R, 3-A Sanitary Standard, CRN, PED, and more as requested.

In addition to custom heat exchangers, Enerquip maintains a complete line of standard heat exchangers in stock for quick delivery. They also produce replacement bundles and parts for existing exchangers.

Markets Served By Enerquip

Enerquip’s custom industrial heat exchangers are used by many leading companies in a wide variety of industries, including:

- Chemical

- Biofuels

- Petroleum Refining

- Pulp & Paper

- Wastewater

- Power

- Asphalt

- Tank Terminal

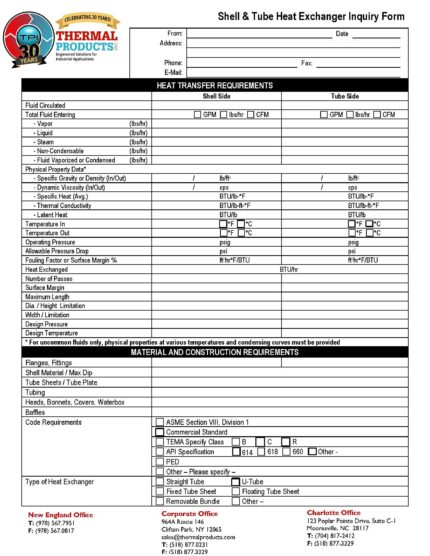

Shell & Tube Exchanger Sizes, Types and Standards

Enerquip’s shell and tube designs are manufactured according to TEMA guidelines with straight tubes, or U-tubes in shells ranging from 2″ to 48″ in diameter. Each heat exchanger will be built according to the requirements of the appropriate TEMA class for your application and environment – Class B, Class C and Class R.

Although Enerquip can design ASME code stamped heat exchangers for operating pressures as high as 3,000 psig, their standard heat exchangers are usually designed for 150 psig at 375 degrees F. They also provide heat exchangers that meet 3-A, PED, and ANSI codes. A CRN (Canadian Registration Number) can be obtained for any of the Canadian provinces.

Materials of Construction

Enerquip fabricates shell and tube heat exchangers from a wide variety of stainless steel alloys, from common 304L and 316L to duplex stainless steels like 2205, 2507 and Zeron 100. They also use corrosion resistant alloys like Hastelloy, Alloy 20, Monel 600, AL-6XN, and copper-nickel alloys.

To ensure high-purity conditions, Enerquip’s shop in Medford, WI, is a stainless steel shop only. They also work with carbon steel, but in their Beggs, OK, facility. Because of Enerquip’s stainless steel buying power, they are normally able to offer a 100% stainless steel exchanger at a competitive price compared to carbon steel. This gives customers higher value and lower maintenance costs on your equipment.

Special Requests? – Just Ask Us!

Customize your heat exchanger to make it work the best for you. Enerquip offers the following options:

- Insulation (non-asbestos and chloride free)

- Horizontal saddles or vertical mounting supports

- Vacuum breakers, sight glasses

- NPT threaded, Sanitary Tri-clamp, RFSO, or RFWN connections

- Davit arms (used with heavy bonnet designs)

- Flow enhanced tubing or twisted tape tabulators

- Floating tube sheets for thermal expansion protection