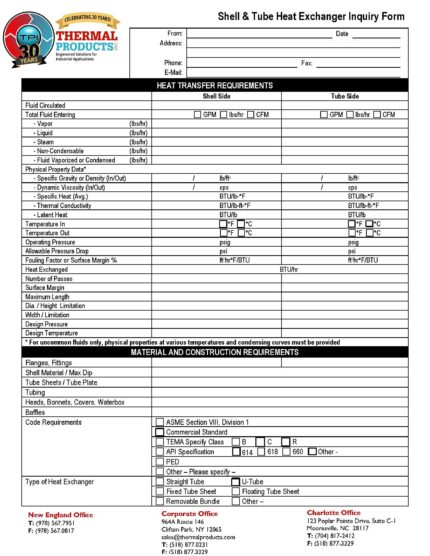

API Basco

API Basco Shell & Tube Heat Exchangers

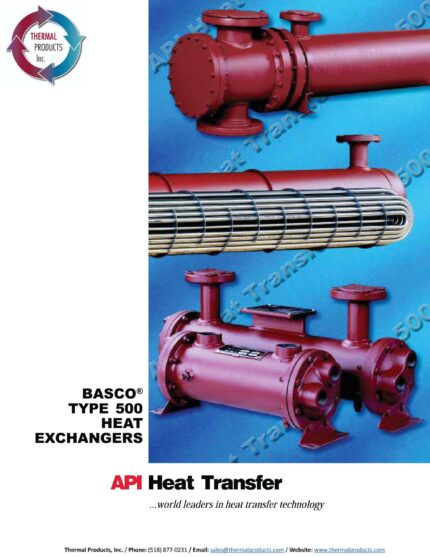

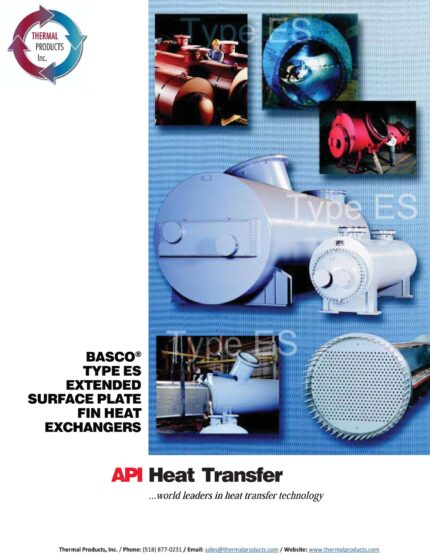

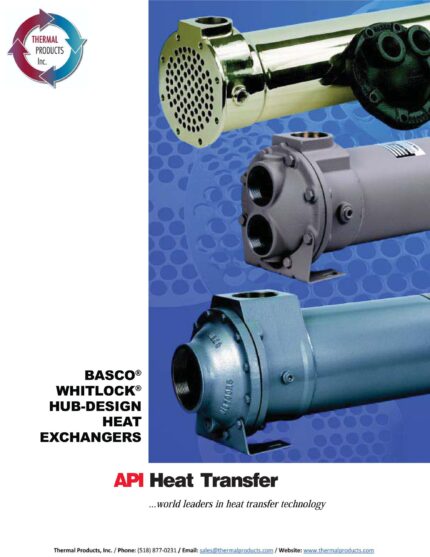

API Basco Type 500, HT, AHT and BWS, OP and TEMA Designed Shell & Tube Heat Exchangers

API Heat Transfer’s extensive line of Basco/Whitlock 500, HT, AHT, BWS, BWU, OP and TEMA designated heat exchangers run the gamut, offering the benefits of ferrous and non- ferrous construction in highly standardized designs or fully engineered, TEMA designated heat exchangers. Standard units are dimensionally interchangeable with heat exchangers made by Thermal Transfer, ITT, Basco, Whitlock, Ketema, Young, and American Industrial among others API design advantages include increased corrosion resistance, maximum obtainment of tube quantity in a given diameter for better efficiency, and lower entrance velocity and pressure drop as a result of the dome shell nozzle.

- Sizes: 2″ to 144″ diameter; 8″ to 600″ length

- Shells: Brass, Carbon Steel or 304 & 316 Stainless Steel

- Tubes: 1/4″, 3/8″, 5/8″ or 3/4” diameter tubes available Copper, Admiralty, 90/10 or 70/30 CuNi, 304 & 316 S/S or Titanium in Straight tube or U-Tube configurations with lofin,BASCOR or plate fin tubing.

- Baffles: Precision punched Carbon Steel, Brass or 316 S/S

- Heads: Cast iron, Bronze, 316 S/S; fabricated heads available in Steel, 304 S/S, or 90/10 CuNi.

- Flow: Available in 1-pass, 2-pass, and 4-pass designs

- Codes: Commercial Standard (non-code) ASME (available above 4″ diameter), TEMA, ASME,ABS, API 614, 660, 618 PED, USCG, Chinese Safety Quality License, Australian Code,Singapore Code, DOSH Malaysian Code, CRN, Polish Code, Indian Boiler Regulations and others. Typical applications: Compressor Systems Lube Oil Consoles Hydraulic Systems Engine Jacket Water Plastic Molding Machines Steam/Water to Water Heating or Cooling Turbine Marine Applications Paint Systems Air Dryers