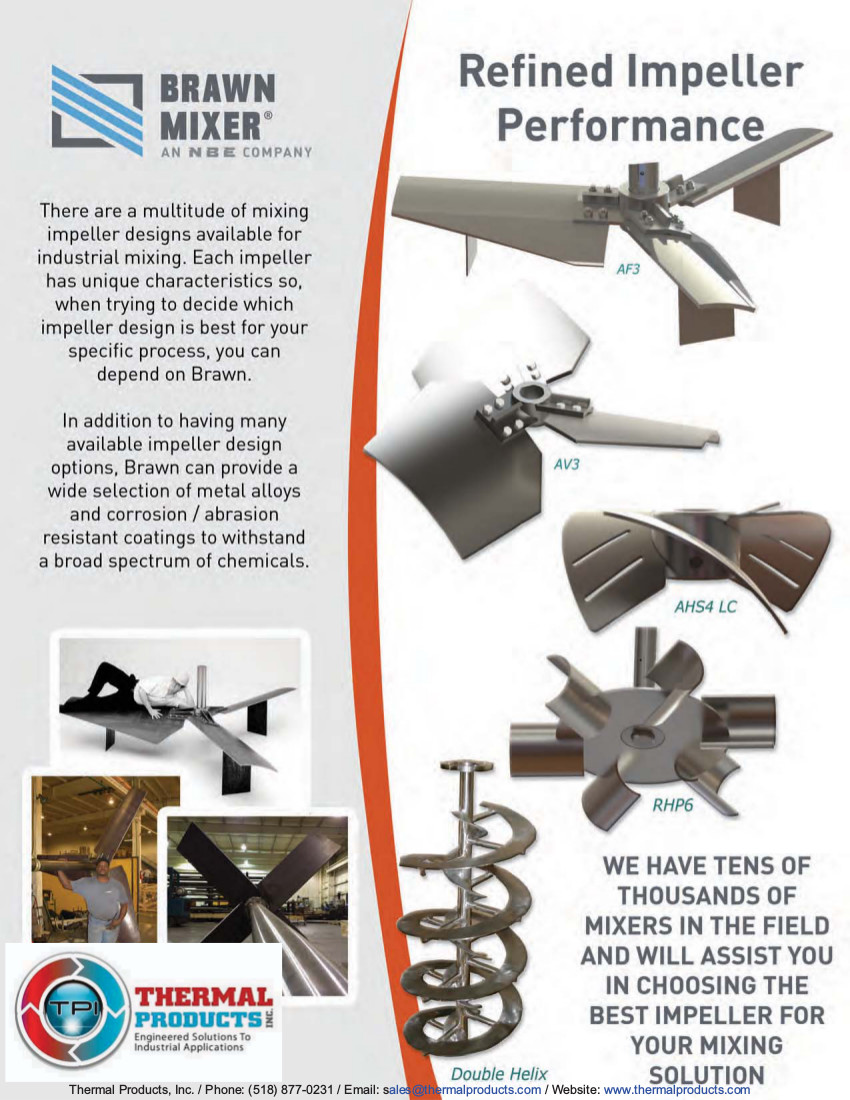

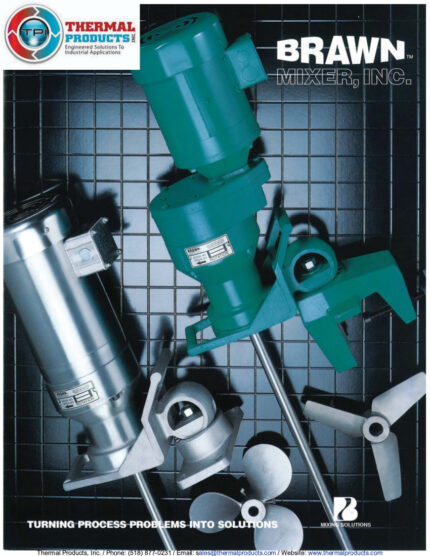

Brawn designs, develops, and manufactures a wide array of impellers for every type of mixing application. Major selection factors like efficiency and cost effectiveness are balanced against optimum process performance to select the correct impeller, rather than trial-by-error specifications that can shorten mixer life or fail to achieve mixing and blending goals.

In addition to many design options, Brawn can provide a wide selection of metal alloys and corrosion / abrasion resistant coatings to withstand a broad spectrum of chemicals. Cleanable and hygienic-spec impellers provide excellent resistance to corrosion and minimize contamination risk. Smooth surfaces significantly reduce localized corrosion processes.

The Brawn Mixer impeller product line is vast in its ability to meet customer needs with High Flow Impellers for blending and solid suspension to High Viscosity Blending and Close Bottom Mixing to High Shear Solids Dispersion, Dissolution, Multi-Phase Dispersions and Emulsion mixing applications.

IMPELLER OPTIONS

Hydrofoils

Brawn Mixer produces a several hydrofoil variants for specific applications. These impellers produce good performance in turbulent flow applications including fluid blending and solids suspension. Hydrofoils pump low viscosity fluids very efficiently, more so than other conventional designs at constant power levels. Some designs have been developed specifically to perform well in laminar flow applications and even in high shear/mass transfer processes. The number of blades, and tip chord angle can be varied to meet your process requirements.

Pitched Blade Turbines

Though the traditional Pitched Blade Turbine is a good all-purpose impeller for a wide range of applications, Brawn has refined the standard design through testing with varied pitch angles, blade width, and other adjustments by application. The results have been tremendous. When conditions call for more flow or varying the energy input, blade angle and shape can be adjusted to achieve the optimum results while retaining the simple cost effectiveness of the basic PBT concept.

Propellers

Propellers remain a low cost option for small batch processes and certain processes requiring more shear.

Specialty Impellers

Anchors, scrapers, and helix impellers are just a few of the specialized designs Brawn has employed for high viscosity and non-Newtonian fluids.

Contact a member of Thermal Products team to dsicuss your mixing and blending needs, today!