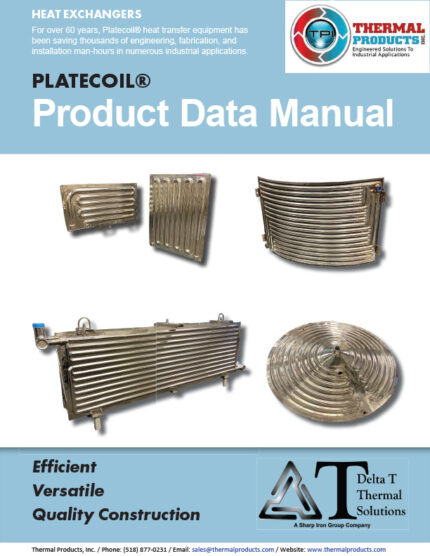

ECONOCOIL

Delta T Thermal Solutions ECONOCOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

ECONOCOIL® is fabricated from two sheets of metal using a fully computerized welding machine that uses electric roll spot resistance welding. The plate is then hydraulically inflated, forming a variety of flow patterns. Each ECONOCOIL® plate is designed and constructed to match the needs of each application and requirement.

We form in all types of malleable metals – carbon steel, titanium and others.

ECONOCOIL® Applications

- Immersion Heaters and Coolers

- Jacketed Tanks and Vessels

- Clamp-On Upgrades

- Heat Recovery Banks

- Fluidized Bed Banks

- Cryogenic Shrouds

- Cascade Coolers

- Freeze Dry Condenser Banks

- Shipboard Heaters and Coolers

- Storage Tank Heaters Shelves

- Glycol Dehydrators

- Paint Solvent Coolers

- Water-Cooled Shields for Electric Furnaces

- Water Chillers for Soft Drink Carbonators

- Valve Warmers

- Banks for Waste Heat Recovery

- Refrigeration coolers

- Refrigerated Liners for Medical Testing Machines

- Suction Heaters

- Screw Conveyer Troughs

- Bayonet Heaters

- Drum Warmers

- Pipe Coolers

- Gas cylinder heaters

- Sanitary/hygienic processing

One of the best benefits of ECONOCOIL® is that it can be produced in an extensive range of custom-made variants when needed for special applications. For example, we can alter the connection location and length, creating an irregular-shaped curved ECONOCOIL® to fit a tank cone end. Another application example is we can weld several plates together to form banks which can be used for large heat exchanger duties and provide accessories to assist with installation and maintenance.