How to understand TEMA tolerances and how they impact your shell & tube exchanger design

When speaking of Shell & Tube Exchangers, we tend to break them into “standard” and “custom” shell and tube exchangers. When we talk of tolerances of flow nozzles and support locations, those manufacturers that belong to TEMA (Tubular Exchanger Manufacturers Association) are expected to build each heat exchangers to within those accepted tolerance called out in TEMA.

See link below for TEMA Tolerances brochure.

Having published tolerances is most important for both the customer and the manufacturer, especially when speaking of “custom” heat exchangers as they are built to a fabrication drawing, without the use of a manufacturing “jig” or “fixture”. Without the use of a jig or fixture, the skilled welder relies on measuring tools, which is fairly precise to the naked eye, but when measured exactly, the dimensions will not exact each time that part is manufactured. Building shell & tube exchangers with nozzle tolerances of +/- ¼” don’t tend to be an issue for process plant or system integrator customer’s as long as it is not more than the noted tolerance. In that instance it would need to be corrected, especially, for a TEMA Shop.

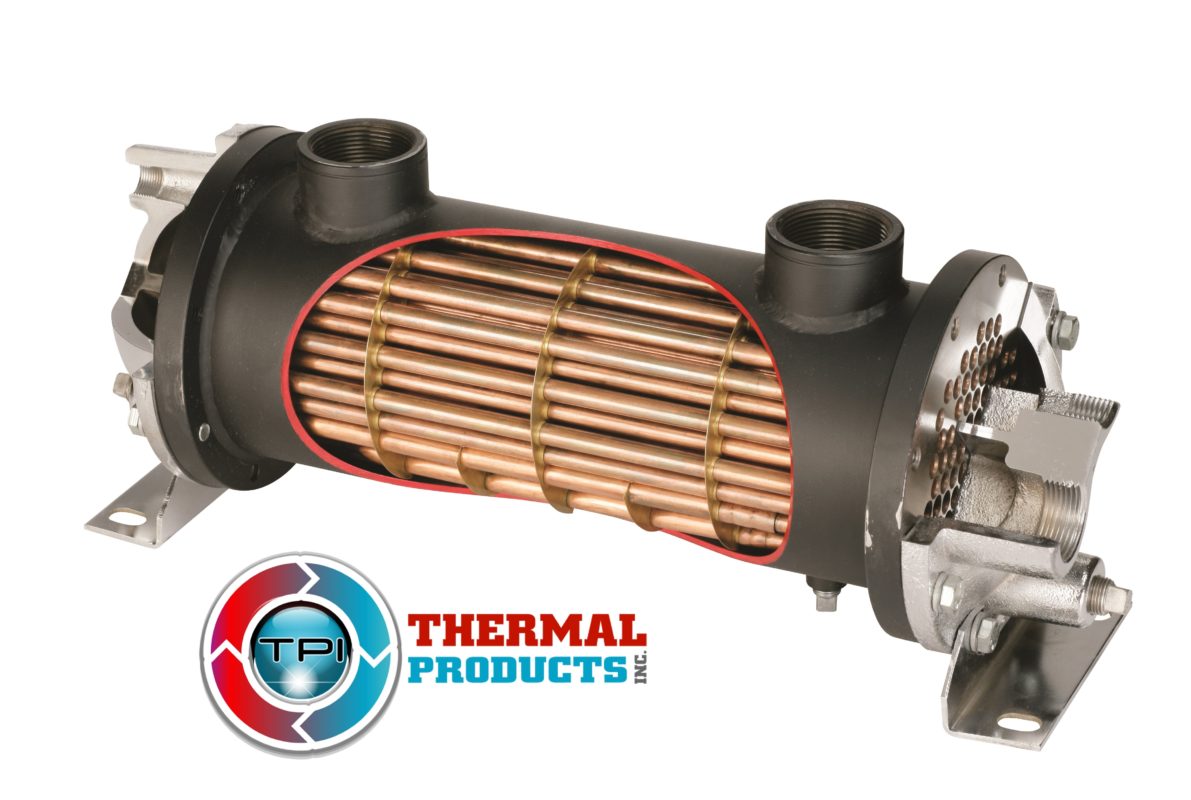

“Standard” heat exchangers tend to be built for OEM customers that rely on exacting dimensions for each delivery of the same shell & tube exchanger. In order to maintain quality assurance of each unit, the use of a jig or fixture to assist the skilled welder is a must. This will ensure each and every part, that is welded together, to make a shell & tube exchanger will have the very same dimension each time it is made. This allows customers to use a Thermal Products heat exchanger, with precision and speed in their product.

Having shell & tube exchanger’s built to precise measurements is also import when looking to replace a heat exchanger in kind. In this case a Drop In Replacement tube bundle or complete heat exchanger is easiest for plant maintenance personal, hospital or school facility engineers, to install. It assures them that they will not need to make any required piping modifications on either the tube side or shell side.

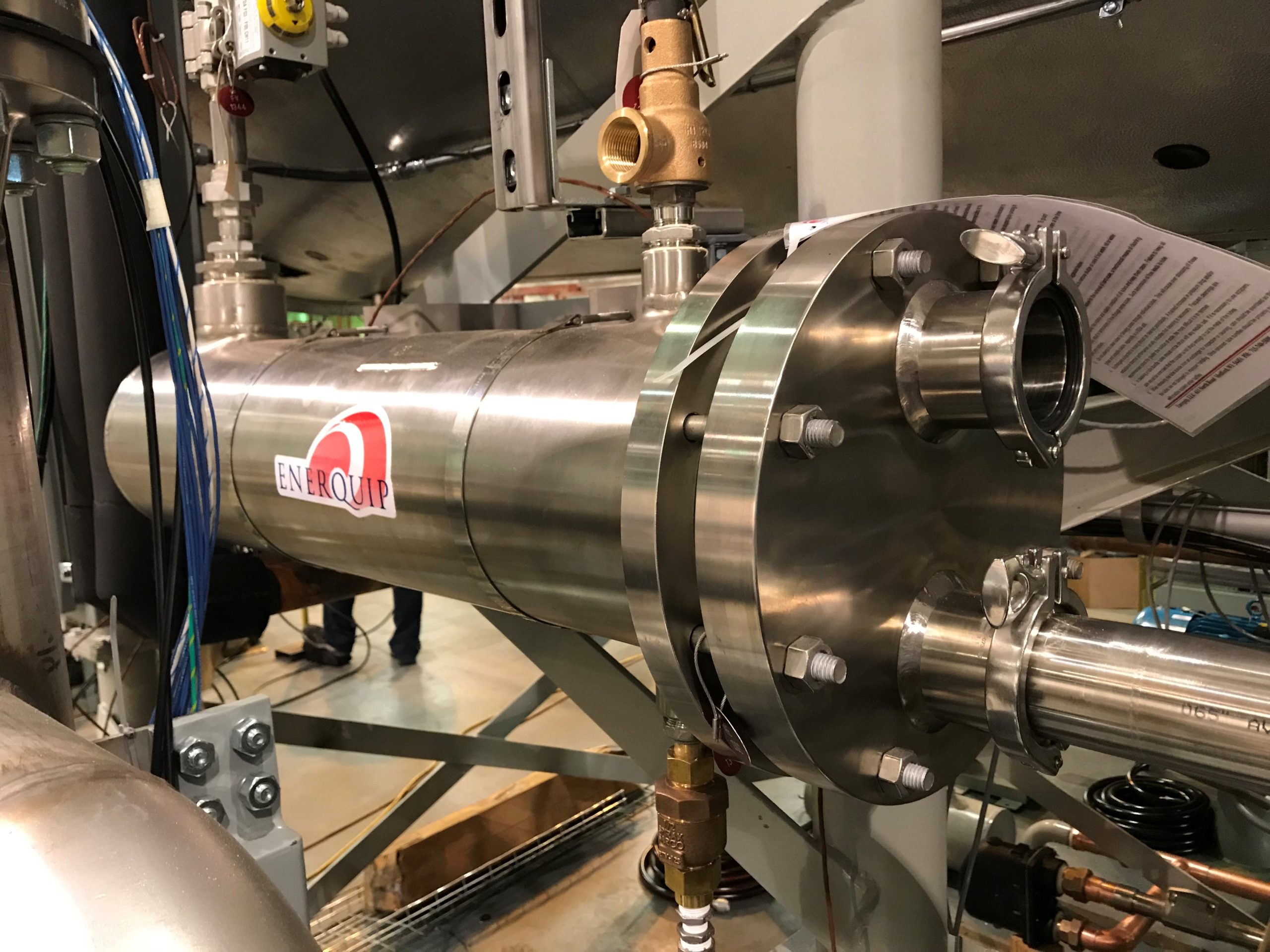

Thermal Products offers Drop in Replacement heat exchanger and tube bundles for a wide range of heat exchanger manufactures. In most cases, Thermal Products will have the needed equipment to manufacturer a NEW heat exchanger or tube bundle that will fit right into place of the old heat exchanger you are removing. If we don’t, we will advise you during the quoting phase and include freight, in our proposal, for you to ship your old heat exchanger to us for duplicating.

If your heat exchanger is custom and can’t ship it to our facility for duplicating, but have a fabrication drawing, we can offer and build a NEW heat exchanger to your fabrication drawing. Please see our latest Drop In Replacement heat exchanger shipment below.