News & Updates

How to reduce the size of your shell and tube exchanger.

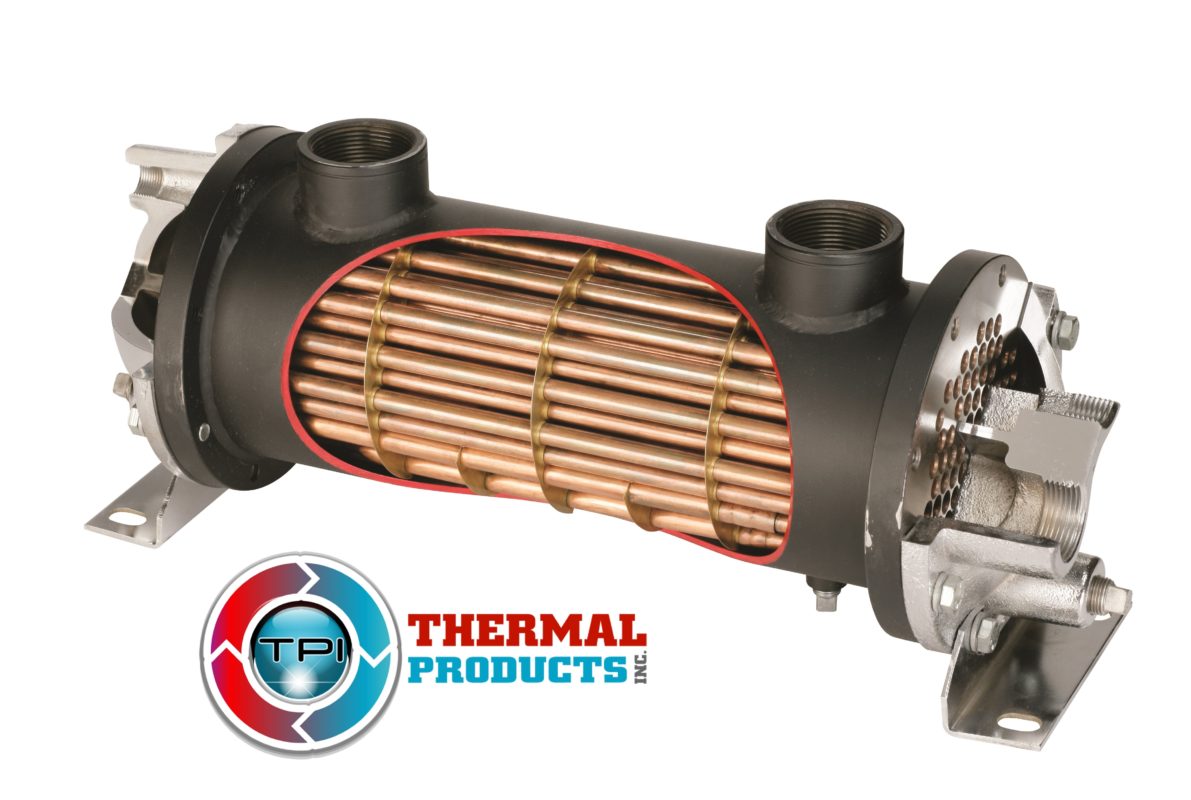

The use of a low finned tube within a shell and tube exchanger is an excellent solution for increasing efficiencies in the cooling or heating of gases and liquids. When space on your lube oil console or fuel conditioning skid is at a premium, see how Thermal Products can offer a smaller shell and tube exchanger design, using low finned tubes reducing the heat exchanger overall footprint and offering considerable potential to save in terms of materials and heat exchanger fill volumes.

The wide range of dimensions offered by Thermal Products Inc makes these products perfect for a broad scope of applications for oil/gas coolers in consoles, machinery and plant processes.

Low finned tubes increase that outside surface area. By having a finned tube in place, it increases the overall heat transfer rate. This then decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project.

Applications Thermal Products has designed low finned tubes within our shell and tube exchangers.

- Power Generation

- Oil and Gas Productions

- LNG NGL LPG Plants

- Refining

- Petrochemical and Chemical Processing

Benefits of Low Finned Tubes:

- Offers 2.5-3 times the external surface area of bare tube

- Enhanced heat exchanger efficiency means less tube is required to accomplish the same heat transfer as a bare tube

- Low finned tube can increase the performance of an existing exchanger without the difficult and expensive task of building new shells etc

- Reduced space and weight can be extremely valuable in offshore production or high elevation distillation columns. Low finned technology can transform large shell and tube exchangers into compact heat exchangers

Contact our team today to discuss your application!