News & Updates

Learn How Thermal Products Can Assist Our Customers in Reducing Fouling in Your Heat Exchangers and Electric Circulation Heaters

Have you noticed decreased efficiency from your heat exchanger or circulation heater? So much so that your process is now operating out of acceptable temperature, pressure drop or flow range? You are most likely having significant fouling issues.

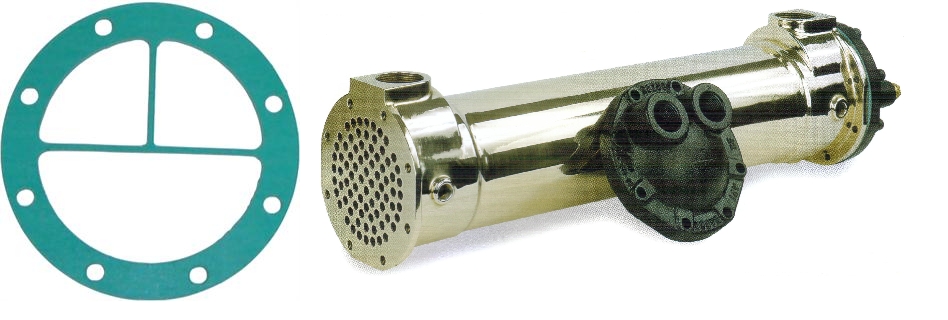

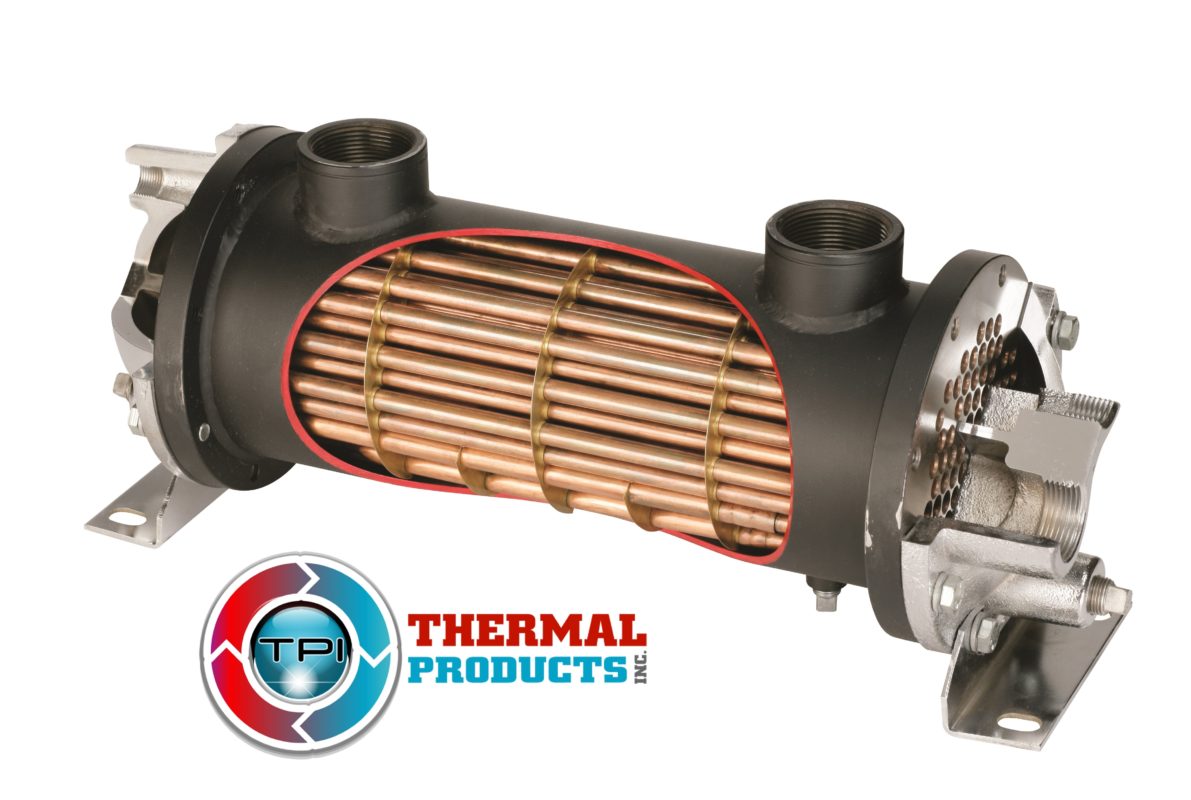

The most common reasons heat exchangers don’t provide the heat transfer rate they were designed for or have increased pressure drop from occlusion, is what we call fouling. Fouling is the buildup of sediments, mineral calcification and/or debris from the process that settles onto the surface area of a heat exchanger or circulation heater.

During the design stage, Thermal Products will inquire about specific process media makeup and the cooling or heating media. Thermal Products will ask you about the suspended solids, mineral content, and chemical content along with the typical needs of flow rate, heat load and temperatures in and out of the heat exchanger. With the provided information the Thermal Products design engineers will take into account the appropriate fouling factor to maximize the lifespan of the heat exchanger or preventative maintenance interval, reducing unexpected costs for the plant. The fouling factor essentially increases the surface area, over and above what is needed in order to perform the required heat load duty.

What are the different types of fouling?

Scaling is one of the most common types of fouling. Minerals and Salts commonly found in natural waters have a lower solubility in warm water than cold. Therefore, when cooling water is heated during the cooling process, particularly at the tube wall or plate wall, these dissolved salts will crystallize on the surface in the form of scale.

Thermal Products will design a heat exchanger or circulation heater with a lower tube temperature or watt density respectively, reducing the tube wall or element temperature. The Thermal Products design engineers will also look at process velocities through the heat exchanger or circulation heater, as slower velocities can exacerbate the problem.

This is noticed typically in the use of cold well water or open cooling tower applications.

Sedimentation, is the depositing of dirt, sand, rust, and other small debris and is most common when fresh water is used. This type of fouling typically leads to the heat exchanger or circulation heater becoming impacted and will completed occlude the flow, if left untreated. This can be controlled to a degree by the heat exchanger design through velocity control, but need to be careful as increasing the velocity too much will lead to erosion of your tubes or elements. Thermal Products will also design and offer upstream filtration or straining equipment to assist in removal of this type of debris before it gets to the heat exchanger or circulation heater.

If your process is sensitive, Thermal Products can design a closed-loop heating or closed-loop cooling process to eliminate the issues of sedimentation fouling completely.

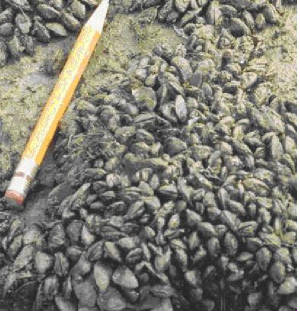

Biological/Organic growth material typically occurs in marine, chemical, or bioorganic applications and can cause considerable damage if allowed to build up. Thermal Products can design a heat exchanger or circulation heater that can be resistant to biological fouling or organic fouling using different materials and design considerations.

Chemical Reaction Coking appears in oil heating applications, where the heat exchanger tubes or circulation heater elements are too hot. When the oil comes in contact, it burns the oil and deposits the resulting hydrocarbon on the heating surface. If left and the situation is not corrected, it will lead to premature failure of the heat exchanger or circulation heater. All oils are susceptible to Coking, but at a wide range of temperatures, dependent on the oil type.

As in mineral Scaling, Thermal Products will require the type of oil used so we can determine its flash point, thermal conductivity, specific heat and specific gravity so we design the proper heat exchanger or circulation heater.

Heat Exchanger and Circulation heater design are far more involved than looking at fouling, but it is an important factor to include when performing the design.

Any fouling, left untreated will result in the failure of that heat exchanger or circulation heater. The failure can be catastrophic in some cases.

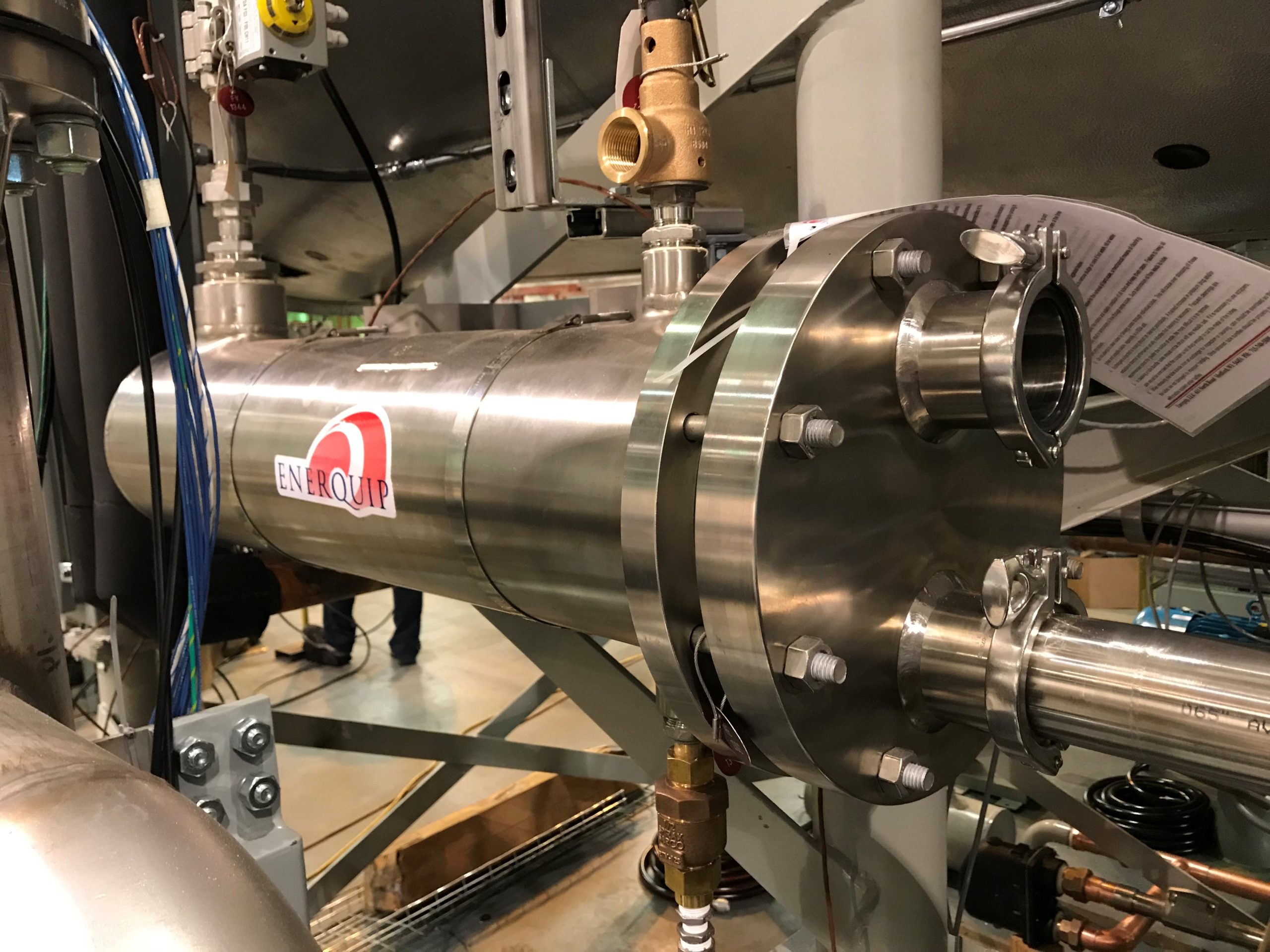

As touched on earlier, Thermal Products can reduce the fouling possibilities greatly, by “closing the loop” if fouling is a chronic problem for your process. Thermal Products can design a Chiller, Closed loop cooling, closed loop heating or offer fired process heaters to perform the heating or cooling as your process dictates.

Contact any member of the Thermal Products team to discuss your process needs.