News & Updates

What is Needed to Design and Quote an Electric Circulation Heater?

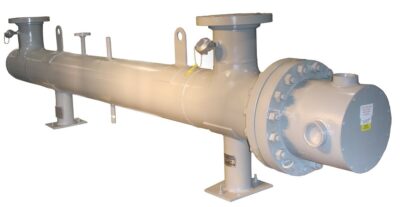

When the design engineers at Thermal Products have a request from a customer to design an Electrical Circulation Heater, we will consider many factors, including:

- What electric codes and pressure vessel standards will guide the design: NEC, CSA, CE, European ATEX, ASME Boiler and Pressure Vessel Code, PED (Pressure Equipment Directive – Europe), CRN (Canadian Registration Number). All guide our engineers to offer the most optimally designed electric circulation heater while ensuring safety, reliability, and efficiency.

- Electrical Area Classifications we can build to:

Class I, Division 2, Groups B, C and D

Class I, Division 1, Groups C and D

Class II, Division 1, Groups E, F and G

UL STD 50, Type 4 or 4X

- Process requirements: Most applications fit into either “Direct Heating” which is once through heating. Or “Recirculation loop” typically between your process or a tank. Usually, a batch or specific heat time scenario for a specific volume of process media to be heated or maintained. For both scenario’s we need the electrical requirements below:

- Voltage

- Any area classifications with temperature code (“T” Code)

- NEMA Rating

- Max watt density requirements, if any

- Control Panel – SCR or Contactors

- What controls are needed?

- Hi-limit thermocouple

- Process thermocouple

- Remote control needs

-

- Direct Heating:

- Media to be heated

- Flow rate

- Inlet temperature and outlet temperature

- Maximum pressure drop allowed

- Operating pressure

- Direct Heating:

-

- Recirculation Loop:

- Media to be heated

- Recirculation flow rate

- Total volume to be heated

- Timeframe to be heated or temperature to be maintained

- Inlet temperature and outlet temperature

- Maximum pressure drop allowed

- Operating pressure

- Ambient temperature worst case cold

- R-value on tank

- Recirculation Loop:

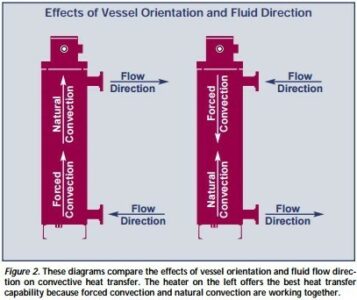

- Configurations: Here our design engineers will consider our customer needs and requests for how their Electric Circulation Heater will look. The available floor space for installation is also a consideration

-

- Horizontal or vertical arrangement?

- Mounting feet needed?

- NPT, Stub-end, or Flanged connection needed?

- Construction materials: Vessel materials can include carbon steel or stainless steel or any higher alloy. Elements can be Incoloy, 316 SS, Titanium, Copper, carbon steel and other higher alloys. Gaskets should be compatible with the process media. We offer many gasket materials and types, but spiral wound and compressed fiber are most common.

Please look for Thermal Products Electric Circulation Heater RFQ form or click here.